Fractionnement à Sec/ Classification par Air

Séparation des Protéines Efficace et Écologique

Le fractionnement à sec est un processus mécanique qui sépare les différentes composantes des grains, graines ou légumineuses sans avoir recours à des produits chimiques ou à de l'eau. Cette méthode est très efficace et respectueuse de l'environnement, ce qui en fait une solution idéale pour produire des concentrés de protéines de haute qualité.

Avantages

Durabilité

Un processus sans produits chimiques qui préserve l'eau et l'énergie.

Haute pureté

Produit des fractions pures et riches en protéines, idéales pour les applications alimentaires.

Rentable

Réduit les besoins en équipements et les coûts opérationnels.

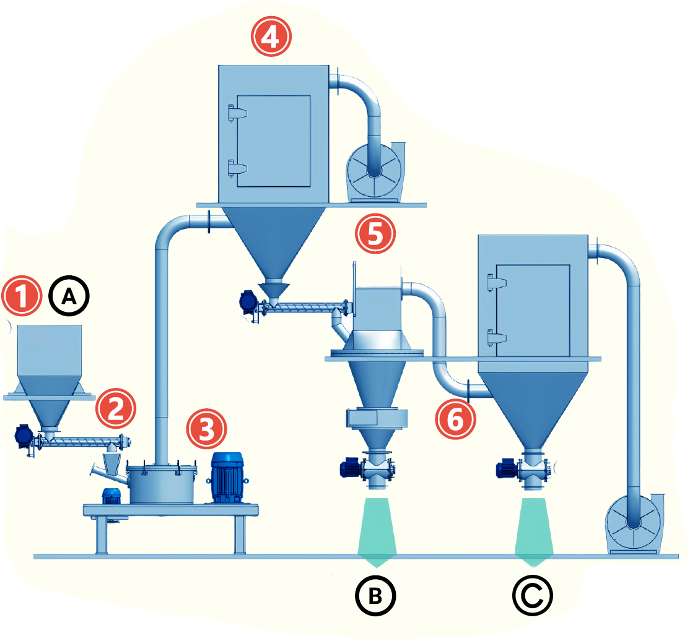

Processus

1. Trémie d'alimentation

2. Vis d'alimentation

3. Broyeur-classificateur

4. Remplisseuse automatique

5. Souffleur

6. Classificateur à air

A. Produit d'alimentation

B. Fraction riche en amidon

C. Fraction riche en protéines

Caractéristiques

Teneur en humidité contrôlée

Garantit des niveaux d'humidité optimaux pour le développement de la texture.

Variabilité de la texture

Capable de produire une large gamme de textures, allant de fibreuses à lisses.

Traitement à haute température

Utilise un contrôle précis de la température pour préserver l'intégrité des protéines.

Applications

Alternatives à la viande

Créez des analogues de viande comme des burgers et des saucisses avec une texture fibreuse et attrayante.

Snacks & céréales

Develop puffed snacks or high-protein breakfast cereals.

Aliments riches en protéines

Améliorez la texture et les niveaux de protéines dans les produits de boulangerie ou les plats prêts à consommer.

Alternatives aux produits laitiers

Parfait pour les produits à base de lait, yaourt et fromage végétaux avec une teneur en protéines améliorée.

Transformez vos produits alimentaires grâce aux solutions de fractionnement à sec de Castle Group. Contactez-nous dès aujourd'hui pour découvrir comment notre technologie durable peut améliorer vos produits.

Nous sommes là pour transformer votre vision en réalité.