Dry Fractionation/ Air Classification

Efficient and Eco-Friendly Protein Separation

Dry fractionation is a mechanical process that separates the different components of grains, seeds, or legumes without the need for chemicals or water. This method is highly efficient and environmentally friendly, making it an ideal solution for producing high-quality protein concentrates.

Benefits

Sustainability

A chemical-free process that conserves water and energy.

High purity

Produces pure, protein-rich fractions ideal for food applications.

Cost effective

Reduces equipment needs and operational costs.

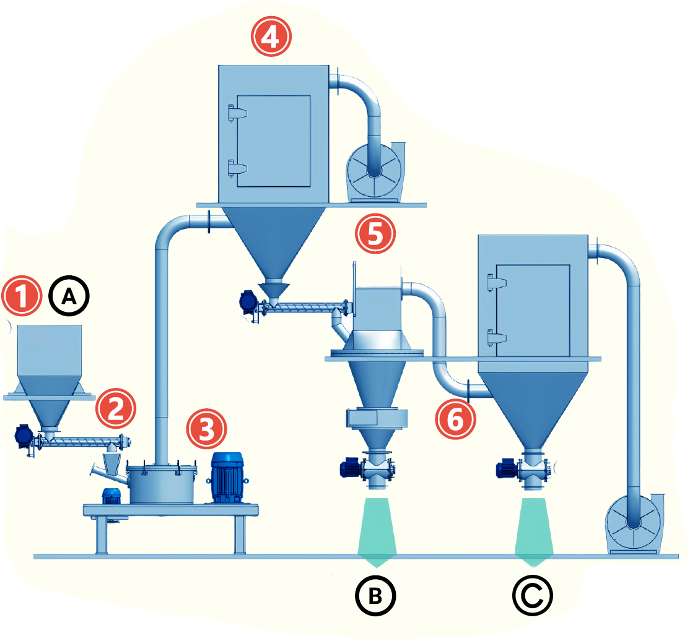

Process

1. Feeding bin

2. Feeding screw

3. Classifier mill

4. Automatic filler

5. Blower

6. Air classifier

A. Feeding product

B. High starch fraction

C. High protein fraction

Features

Controlled moisture content

Ensures optimal

moisture levels for texture development.

Texture variability

Capable of producing

a wide range of textures, from fibrous to smooth.

High temperature processing

Uses precise

temperature control to maintain protein integrity.

Applications

Meat alterna

tives

Create meat analogs like burgers and sausages with a fibrous, appealing texture.

Snacks & cereals

Develop puffed snacks or high-protein breakfast cereals.

High protein food

Improve texture and protein levels in baked goods or ready-to-eat meals.

Dairy

Alternatives

Perfect for plant-based milk, yogurt, and cheese products with enhanced protein content.

Transform your food products with Castle Group's dry fractionation solutions. Contact us today to learn how our sustainable technology can boost your products.

We're here to turn your vision into reality.